The sampling plan for the expanded study will quickly grow beyond a reasonable size and will require reducing the sample size of at least one variable. Note If there are less than 10 observations per operator, Minitab displays an individual value plot instead of a boxplot.

Minitab gage r&r how to#

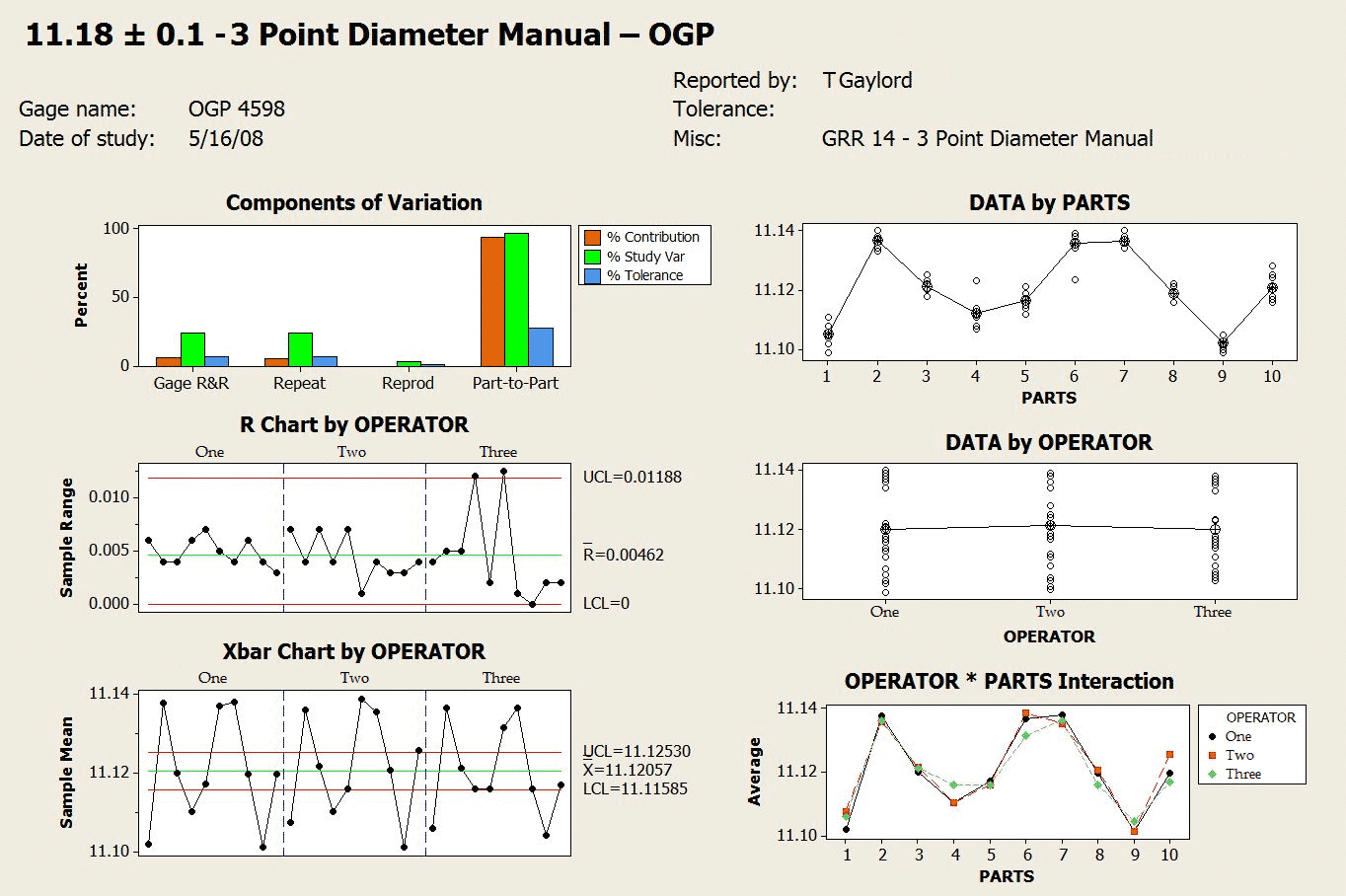

Learn how to utilise data for continual process improvement & better decision. However, with an expanded gage R&R study, you can graph other factors. The interactions of the additional factors with operator and part can also be evaluated.Ĥ. Training course on Minitab, leading general purpose statistical software. Unlike the standard study, missing data points are allowed in the analysis for an expanded study.ģ. The expanded study allows additional factors such as gage, laboratory and location to be evaluated in addition to operator and part.Ģ. The four main differences between a standard and an expanded study are:ġ. The Total Gage R&R percent tolerance of 3% was so low that the shop was able to reduce QA sample size while maintaining the same level of quality. Our SOP tells us to use a nested Gage R&R study in Minitab, but it wont work when I feed it data (Part 1-10 for operator 1, part 11-20 for operator 2, part 21-30 for operator 3) - 'ERROR - there are no replicates.

Minitab gage r&r manual#

They did an Expanded Gage R&R, including operator, part and gage. Acceptability Criteria for R&R ( of Total Variation and of Tolerance) AIAG uses <10, but within Motorola <5 is preferred (Note: For R&R smaller is better) Based on the AIAG Measurement Systems Analysis Reference Manual - Call 81 to order. Since any measurement technician could use any of dozens of gages, a standard Gage R&R could not demonstrate capability.

Minitab gage r&r verification#

Customers require verification of the capability of their dimensional measurement systems. After the manufacturer calibrates the gages to one standard, rejects are virtually eliminated.Ī California machine shop produces stainless steel parts to extremely tight tolerances for use in robotic surgical instruments. A percent tolerance greater than 30% is considered unacceptable. It then uses total variation to determine. The calculated percent toler-ance-the proportion of the tolerance that is taken up by the measurement system variability-is 79%. Stat > Quality Tools > Gage Study > Create Gage R&R Study Worksheet. Gage repeatability and reproducibility calculates the total variation (TV) from three factors. The manager conducts an Expanded Gage R&R that includes the three gages as well as operator and part. Faced with an unacceptably high reject rate, the quality manager suspects the measurement system is at fault, but each gage has been calibrated to its own standard and passed its Gage R&R with flying colors. In the following situations, a third factor is crucial to understanding the system.Īn electronics manufacturer makes voltage regulators on three production lines, each with its own gaging system.

When three or more factors are included in the analysis, we call the study an Expanded Gage R&R. Adding a third variable (typically gage) to the standard study is often required. However, the effects of operator and part frequently are not enough to provide a complete understanding of the measurement system. Most Gage R&R studies assess the effects of two factors on variation in your measurement sys-tem-typically operator and part. The most common type of MSA is the Gage repeatability and reproducibility (R&R) study. Whether you're engaged in a Six Sigma project or an IS09000 certification, an MSA helps you identify problems with your measurement system and determine if you can trust your data. That's why Measurement Systems Analysis (MSA) is a key component of establishing, improving and maintaining quality systems.

However, it is possible to do EMS in the Fit Model platform in JMP.If you can't trust your measurement system, you can't trust the data it produces. There is no way to "force" EMS within the Variability platform because REML gives better (less biased) estimates when there are negative variance components that need to be zeroed.

0 kommentar(er)

0 kommentar(er)